Tasting Parma Part Three: Prosciutto di Parma

The town of Langhirano serves up two special things. The first is the Castle of Torrechiara which I saw off in the distance on my way to the even bigger attraction - a salumificio, a place where prosciutto (along with other pork products) is produced. The castle is by far the prettier of the two attractions, but it is the production of prosciutto that really defines this town set in the hills near the city of Parma. And prosciutto is what I came to see on this, the final stop on my tour of the foods of Parma.

The first thing I learned during my visit to the Salumificio Conti was to never, ever refer to the product produced here as simply “prosciutto”. Prosciutto is a generic term for a non-smoked, air-dried ham either crudo (raw) or cotto (cooked). It is produced in several regions and is not a protected product name. The delicacy produced in this family owned salumifico is anything but generic. It is known by its full name - Prosciutto di Parma. This special, high quality type of prosciutto crudo is only produced in this region and under strict regulation. It is a controlled process, a quality tested end-product, and bears a DOP designation (in English its PDO, Protected Designation of Origin). Calling it plain old proscuitto just won’t do!

First, a little bit about the Salumificio Conti. The Conti family came to this part of Italy some 200 years ago, working the land and raising animals. In 1968, two of the Conti brothers founded the salumificio and learned the process of curing ham. Today the family does not raise the pigs themselves, they buy the hind legs of specially bred pigs (the types of pigs are part of the DOP regulations). Today the production is completely run by the women of the family, Mariangela and her three daughters, Michaela, Francesca, and Daniela. They do everything from minding the storefront, giving the tours, providing the tastings, and supervising the handling of the meat from raw hind leg to finished product. I have to think that their touch makes the meat ever so much tastier. To learn more about the history of the salumificio, there is a small museum on site with photos, old tools, and a timeline of the evolution of this family business.

The hills around Langhirano have a microclimate that contributes to the unique flavor of Prosciutto di Parma.

So, just what makes Prosciutto di Parma so special? Of course, it begins with the pigs (with apologies here to my vegetarian friends). Not just any pig will do. These are Italian born and bred pigs who are monitored from birth and must be at least 9 months old, weighing around 160 kg before they can begin to become Prosciutto di Parma. Each is even tattooed with the “parma crown”. They are fed a specific diet, which includes the whey that is a by-product of the production of parmesan cheese (another famous local product). This contributes to the flavor of the finished product, which is deeper in flavor and less sweet than other types of prosciutto.

Another factor is that this is a completely natural product. Salt is the only seasoning used in producing Prosciutto di Parma. There are no additives or preservatives added to the meat. In fact, our tour guide emphasized that the magic combination was pig + salt + sea breezes + time. It sounds simple enough, but the process is still quite involved.

Sea salt is the only seasoning added to the raw pork (photo from Conti website)

The hind legs arrive at the facility and are weighed. If too large, they are used for other products (such as Culatello and Fiocco, both of which have added spices and different methods of production). Next, the legs receive a good massage with sea salt crystals. Originally done by hand, today there is a machine for this part of the process. The next step in the curing process is cold storage in high humidity. The legs are first laid flat, to provide a bigger surface for salt absorbtion and to give the classic flattened shape. Later, they are hung in the same cold storage for 60-90 days.

Next, comes the sea breeze part. The legs are hung from large wooden frames in a low humidity environment for several months. In the past they were actually outside on the roof top so as to catch the sea air. Health regulations prevent that open air drying these days, but the drying rooms have screens to let in the sea breeze. It’s an essential part of the process!

Outdoor aging to catch the sea breeze the way it was done in the past. Today this step in aging is done indoors with screens to let in the sea air.

The white coating on the cut end of the leg is the sugna, it prevents the meat from drying out and keeps it soft.

The legs are coated in sugna, a mixture of lard, salt, pepper, and rice flour).

The purpose of this mixture is to seal the meat and soften the cut surface. It is not absorbed and does not contribute to the flavor.

Last step - to the aging cellar. Here the meat rests for at least 12 months.

At the end of the period of aging, an inspector from the local consortium arrives to certify the meat. What an interesting process that is!

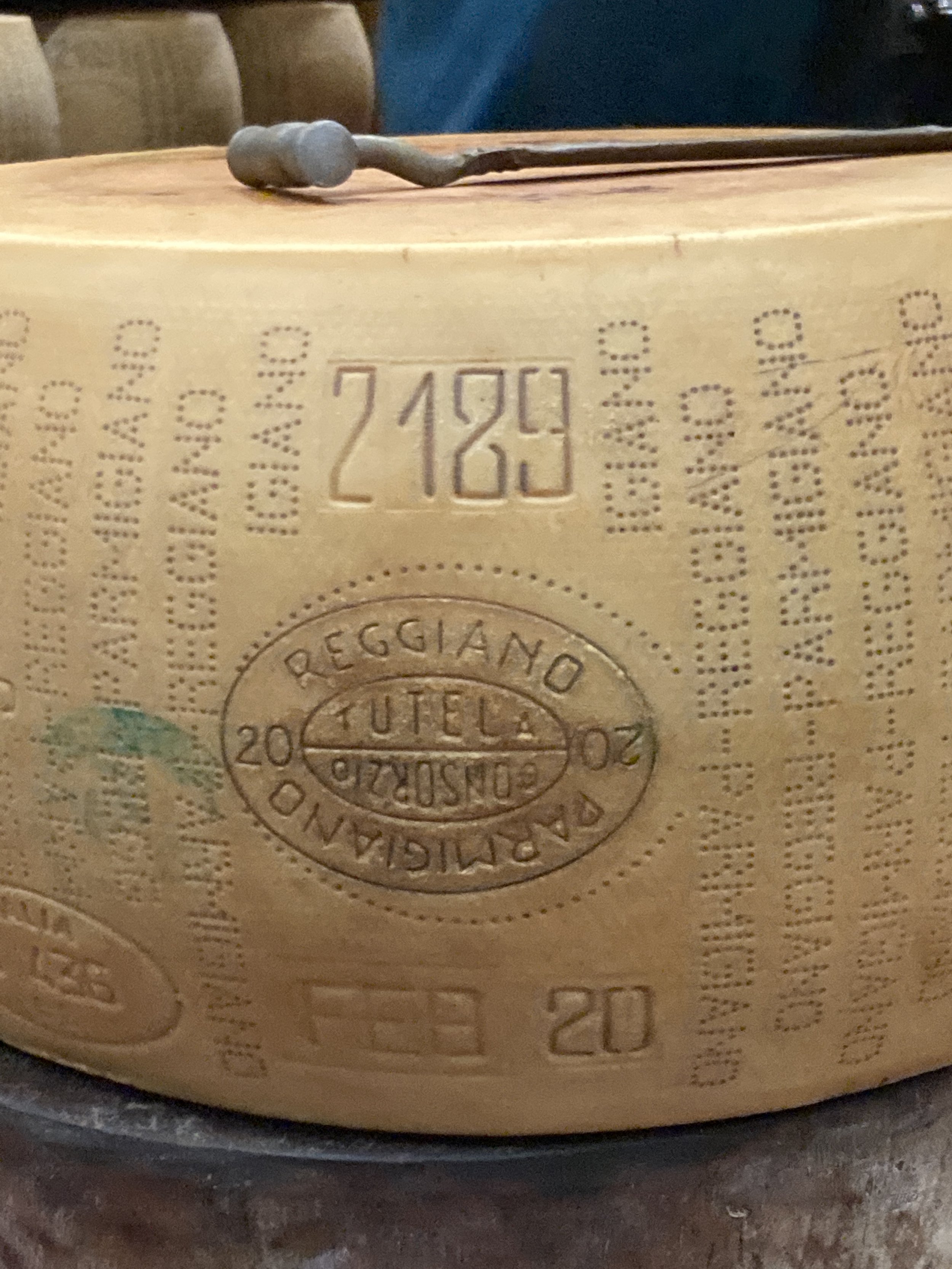

A needle like device made from the bone of a horse is used to puncture the prosciutto in several places. This type of bone picks up scent easily and the inspector sniffs the bone to determine if the meat has spoiled or is good. If it passes inspection it is branded with the Parma Crown and the number assigned to the producer.

This aged Prosciutto di Parma is branded with the Parma Crown, signifying it has passed inspection.

During the long process of aging, the producer is never quite sure how much of the meat produced will be good. This factor contributes to the cost of DOP certified Prosciutto di Parma.

After the tour we were treated to a tasting which included both Prosciutto di Parma (silky, almost buttery smooth, and exquisitely flavorful) along with some of the other pork products produced at Conti (delicious). Of course there was some wine too!

My Parma food tour was arranged by the company Get Your Guide. It was a well organized and fun way to see three places in a single day and learn about the production of Parmigiano Reggiano (Part One of this 3 part post) and Aceto Balsamico (Part Two). Of course Parma has much more to offer than just food. Look for more of Parma in future posts.

Contacts:

Salumificio Conti website: contiproscuitti.it

Get Your Guide website: getyourguide.com. (there’s also a helpful app)